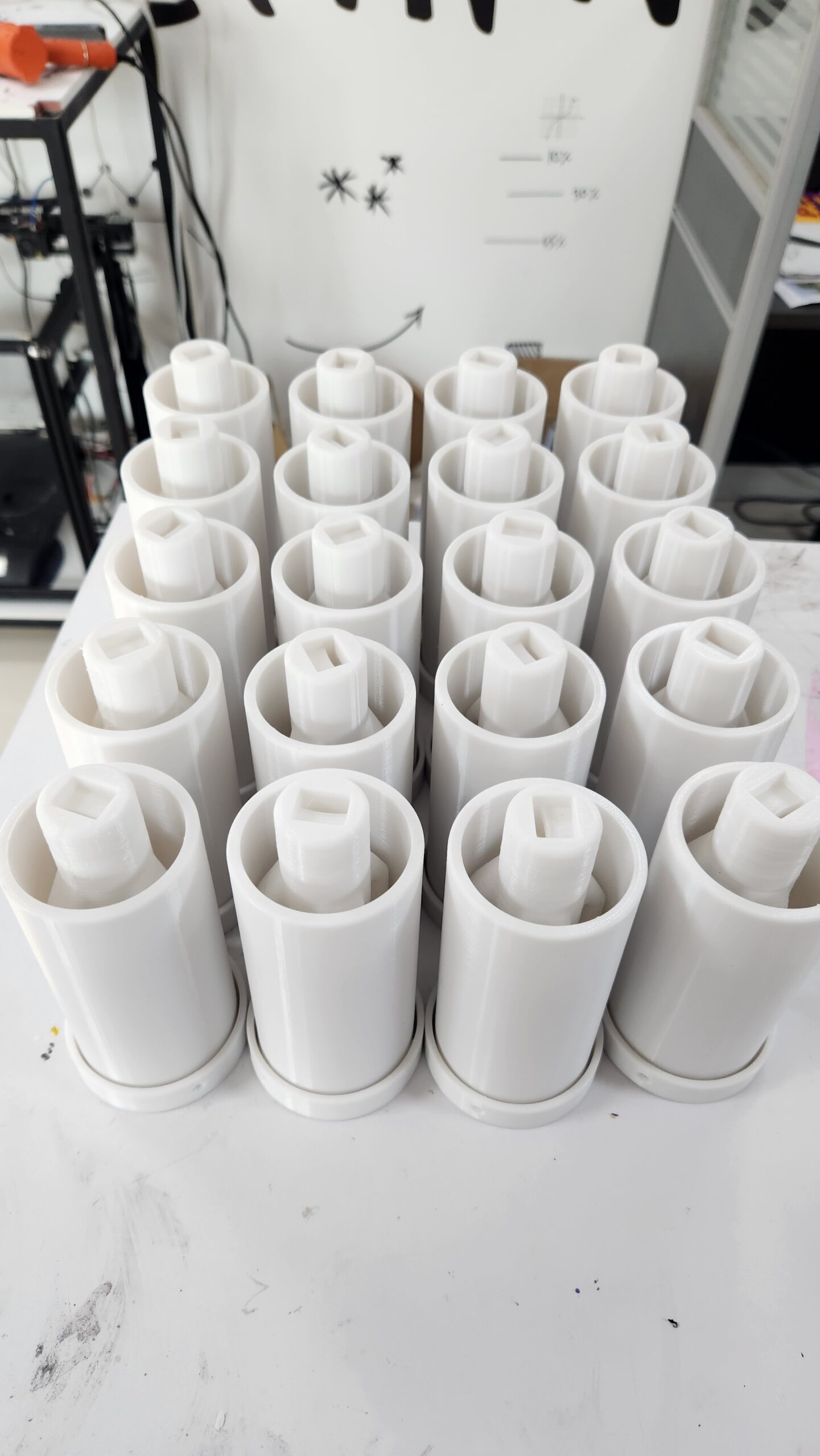

Low-volume production with 3D printing technology offers a revolutionary approach to manufacturing small batch runs of specialized products. This process allows businesses to meet specific demands without the high costs associated with traditional production methods. Whether you’re looking to create custom products or streamline your manufacturing process, 3D printing is a flexible, cost-effective solution for producing low volumes efficiently.

By leveraging 3D printing for low volume production, businesses can quickly and cost-effectively create specialized products or test new concepts, all while maintaining flexibility in design and production.

Low volume production using 3D printing involves several key stages to move from concept to the final product. The process is streamlined, efficient, and ideal for small-scale, customized production runs. Here’s how it works:

Q: What types of products are suitable for low volume production with 3D printing?

Q: What 3D printing methods are used for low volume production?

Q: Can I make modifications to the design during the production process?

Q: Is 3D printing suitable for large-scale production?

Experience the Future of Creativity, Turn Your Imagination into Reality Through 3D Printing

Website Designed & Developed by Digimaxcreatives.com